Never Cut Out A Valve Again

Article published by: The Combined Cycle Journal

Download the Full Article

“We all understand the impact of having to wait for your next outage season to do repairs,” says Aaron Florek, executive director, Millennium Power Services (MPS). “Our president, Michael Pellegrini (Fig 1), recognized this problem and worked for years to develop our new MPS-YPG globe valve.”

(Fig 1), recognized this problem and worked for years to develop our new MPS-YPG globe valve.”

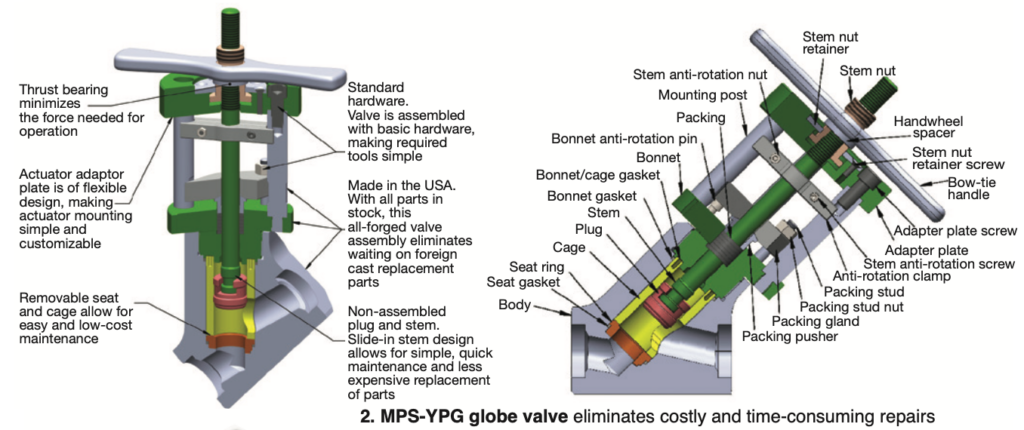

Drawing on 35 years of valve experience, Pellegrini and the Millen- nium team developed a valve design they believe solves the very common and recurring problem of leaking valves. Florek says the “MPS-YPG valve is the perfect solution for your typical high-maintenance block-valve application. It is truly repairable in the field without the need to be cut out of the line.

“Our SmartTrim design (Fig 2) enables fast, on-the-fly repairs. Every component of the new valve is designed to minimize maintenance, saving you time, cost, and manpower.”

Highlights:

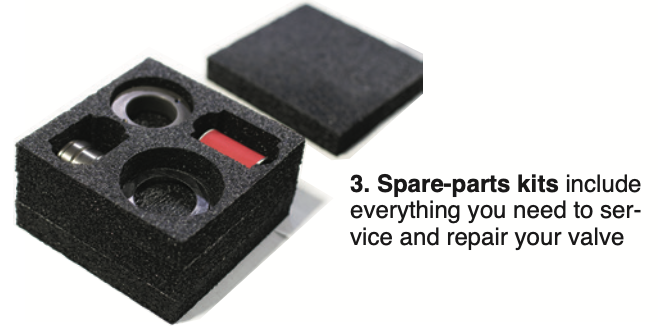

- Repair kits (Fig 3) include everything you need to service and repair your valve in less than an hour, versus having to wait until the next outage season. The removable seat eliminates the risk of long shutdowns to perform in-line machining on seating surfaces. No grinding or welding, just remove the seat and install a new one.

- Swapping or changing actuators is simplified. The adapter plate shown in Fig 2 gives the owner/ operator a range of flexibility when choosing to attach its preferred actuator.

- Replacement parts are always in stock and readily available from MPS. Parts are either made in house or are common hardware.

- The 2-in. MPS-YPG valves come with F91 and F22 bodies and meet all the requirements of ASME B16.34.

Wrap-up.

Along with this new valve offering, Millennium Power Services is your single-source vendor, specializing in manufacturing, welding, reverse engineering, field services, and ability to bring to the customer its mobile machine shops. “We really can do it all,” says Florek.